I will introduce the way of making the case which used the acrylic board on this page.

I used "Bending apparatus-2" to bend the acrylic board.

Drawing of case Drawing of case

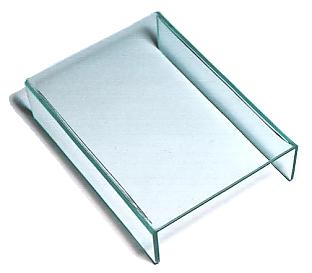

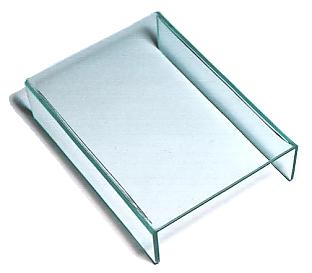

Bottom Bottom

The after work is easy when bending a cover installation part first.

Cover Cover

A glass colored acrylic board was used for cover.

I made a cover after making the bottom.

The cover is bent according to the size of the bottom.

To make length on either side the same, I was cut after the bend of the cover was ended.

Making holes Making holes

For fixation the terminal For fixation the terminal

It makes holes to install a terminal for the output signal. To decide the position of the hole, I used the printed back panel to the paper.

For fixation the power supply connector For fixation the power supply connector

It makes a hole which installs a power supply connector. To decide the position of the hole, I used the printed back panel to the paper same as terminal. It makes needed size using the reamer because it isn't opened only by the drill. If approaching needed size, it confirms size frequently.

For fixation the anntena For fixation the anntena

To decide the position of the hole, I used the printed back panel to the paper.

For fixation the control board For fixation the control board

It mounts the control board on the center of the case. The power supply connector has depth. So, it pays attention so as not for the screw of the board to touch.

For fixation the cover For fixation the cover

This time, I mounted screws for the fixation on the side of the case. Because the thickness of the acrylic board which was used this time is 2 mm, it can make a directly female screw at the acrylic board, too. I made a female screw using the brass board with 3-mm thickness. It is fixing a brass board on the bottom using the plate screw of 2 mm.

|