Cool-Amp silver plating

|

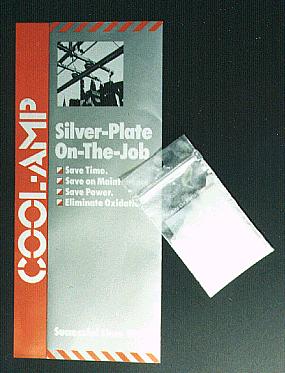

I introduce silver plating by the Cool-Amp as the Eliminate Oxidation of a printed board on this page. Mr. Hans Wedemeyer introduced me the Cool-Amp. I demanded the free sample to the Cool-Amp company and acquired it. In May 2002, the distribution of the sample seems stopped. The details see the following page.

|

||||

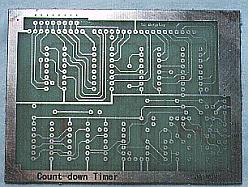

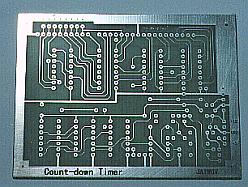

The Cool-Amp was developed in the purpose to make a good electrical contact between two bolted or stationary pieces of copper, brass, or bronze connections. It silvers the aspect of the connection and it diminishes a contact resistance. It is to apply powder to the connection surface only without needing special equipment and that it is possible to do silvering that are epoch-making. In addition to contact resistance's decreasing, there is a preservation effect(Eliminate Oxidation). I used this in the purpose of the preservation. Mr. Hans explained to me the following instructions. When using the Cool-Amp for the printed board, it applies before drilling holes. Place a little Cool-Amp powder in a separate flat container, this way you do not contaminate the stock powder. Keep the Cool-Amp in a dark place when not using it. OK to use in normal light. Make a small pad of cloth, moisten pad with water. This you will dip into the powder. Then rub in small circles all over the printed board. Keep pad moist and keep dipping when you need more powder. Work on soft surface. I place a paper towel on my work surface and place the printed board on it, then the bottom side of the printed board does not get scratched. Keep rubbing the Cool-Amp onto the printed board and in a few minutes you will see the surface changes to a dull grey and as you continue it becomes bright silver. I rub for extra 2-3 minutes to makes sure the coating is thick. Wash in water. Dry, Drill, Assemble... Soldering is just as normal. The instructions of the Cool-Amp which is attached to the sample is shown below. The Cool-Amp deals with the electric installation. It isn't mentioned about the application to the printed board to the instruction. In the following instruction, the item which doesn't have relation in case of the printed board makes the color of the letter thin. INSTRUCTIONS

This is the "Cool-Amp" method of making a good electrical contact between two or stationary pieces of copper, brass, or bronze connections. 1st.

Any silver plated surface that has become discolored or tarnished, due to age, or weather, can be restored by the 4th and 5th step. GENERAL HINTS

Wash hands before placing them on silvered surface, as particles of paste or powder on them will spot the silver. Some problems may arise, but a little ingenuity will always solve it. Such as a tooth brush to silver a threaded stud and a thin wood paddle with rag, between switch clips. A soft paste, made with table salt and vinegar, applied with a tooth brush will clean threaded copper studs or other irregular forms, but must be washed off before silver plating.

|