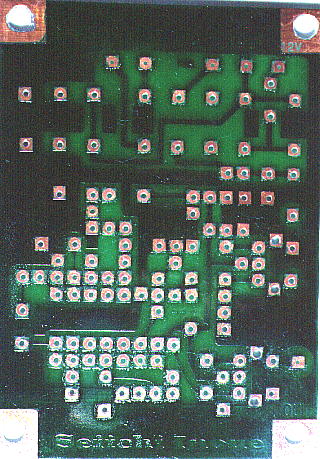

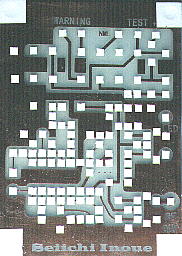

Apply the solder-resist (option)

Generally, it is not in the necessity to paint the solder-resist. Generally, it is not in the necessity to paint the solder-resist.By painting the flux, the oxidation of the copper foil is prevented. The solder-resist is applied for the oxidation prevention and the adhesion prevention of extra solder. The purpose to paint the solder-resist when making the printed board, being homemade is for the purpose to make the oxidation prevention powerful and the beauty. The part which painted the solder-resist gets for the solder not to be stuck. Because it is, mask and paint the part which solderings the lead line of the parts. This is the troublesome work. Cut the seal small and set to the soldering part. I cut the seal in the 3-mm square and used it. Because it is peeled from behind, use the one which is easy to peel off. If pasting the seal to all the soldering parts, apply the solder-resist. I used the sprayer formula. Apply once and make dry up. Again apply, dividing as much as the three times. With this way, the finish becomes beautiful. If the application ends, make dry up and peel off the seal of the mask. It is possible to peel simply when picking with the thin wire through the hole from the component side. |