Apply the flux

[Menu]/[Manufacturing of Original PCB]/[The process of the PCB making]

|

The printed board that the etching was ended has the sensitizer for the mask. If there is necessity, it makes the size of the printed board the size of the last before removing the mask. The following way is simple to remove the sensitizer.

As the other way, it is possible to remove using the resist solvent, too. Remove the part which was corrected with the resist pen and so on in this way. There is a way of wiping up after spraying the absolute alcohol, too. You do until the copper foil in all wiring parts becomes beautiful. |  |

|

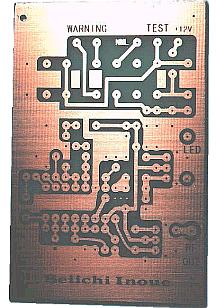

The copper foil of the printed wiring which removed the mask becomes the condition that it is easy for the surface to oxidize. When leaving just as it is, the oxidation discolors blackly of the surface of the copper foil and soldering becomes difficult. To prevent from the oxidation of the copper foil, the flux must be applied. The flux is the liquid which has the stickiness little. It is the knack that, when painting, it paints quickly. The stickiness of the flux becomes strong when painting slowly and it isn't possible to paint it beautifully. After painting the flux, it makes dry up sufficiently. By applying the flux, soldering, too, becomes easy. |