|  |

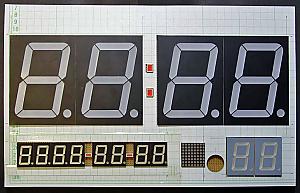

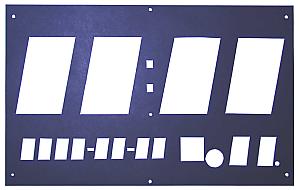

| Thick paper is cut in the size of a case and clipped according to the outside of LED. The place cut too much sticks and corrects paper. | This is a complete mask. The circular hole in the lower right is the hole which installs a speaker. |

|

|  |

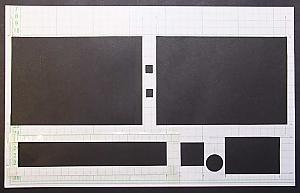

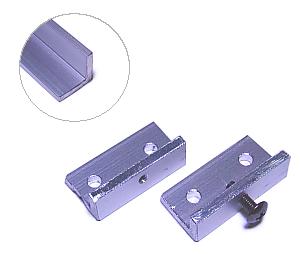

| This is in the state which attached the mark of the portion cut off using a mask. Since the thin vinyl sheet on the surface is stretched, if it removes after finishing making holes, a mark will disappear. | Since the area to cut off is large, a reinforcement stick is attached before cutting off. The plate screw is used for attachment of a reinforcement stick. Therefore, the surface is even. |

|

|  |

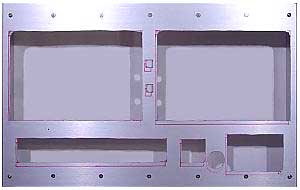

| It cuts off the inside of a little of the mark using the thread handsaw. A reinforcement stick is hit in the position of the drawn mark. Therefore, the position to cut was moved a little. | It enlarges a hole to the size of the display panel using the file. Even if a hole is somewhat large, in order to attach an acrylics board to the surface, there is no problem. |

|

|  |

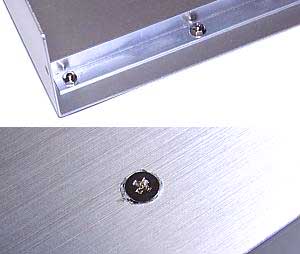

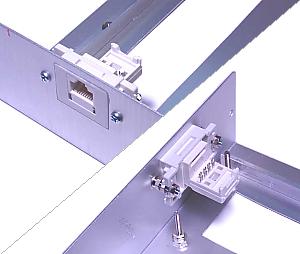

| LED of a display panel is adjusted to the same height as the surface of a case. In order to prevent change of the adjusted height, it fixes with a double nut. | RJ-45 connector for connecting with a receiver is attached in the left-hand side of a case. |

|

|  |

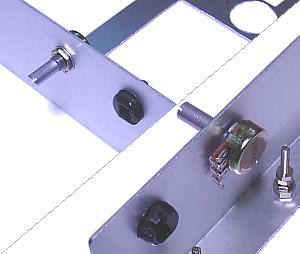

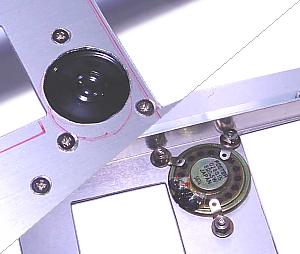

| The variable resister which adjusts the volume of a time signal, and the hole which lets AC cable pass are made in the right-hand side of a case. | The speaker which I used does not have an attachment part. Therefore, I fixed it using the lug terminals. |

|

|  |

| In order to raise the intensity of the center of a case, I attached the screw. L angle of 3mm thickness was used for the female screw side. | Metallic ornaments are fixed to the back lid of a case. |

|

|  |

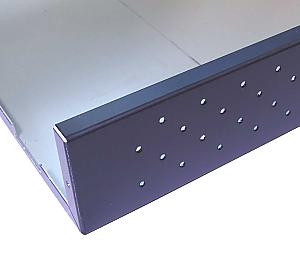

| Some air holes are made in a back lid. | This is in the state which the case completed. |

|

|  |

| In order to hide the unnecessary portion of LED, a bandage mask is made from black paper. Paper is stuck on the mask which was made to open holes and the pattern of a bandage mask is made. | This is the completed bandage mask. |

|

|  |

| This is in the state which placed the bandage mask. | A purple acrylics board is attached at the end. |

|

|  |

| Some small holes are made in the position of a speaker so that sound may pass. | During work, in order to prevent the crack of an acrylics board, a panel is covered with a soft protection sheet. |

|

|

|

| This is in the state which attached the chain for wall tapestries in the back of a case. |

|