|

The electronic circuit that was completed is housed in the case.

It must make the hole that passes wiring and also make the hole for the screw to attach the circuit to the case.

The instruments like the following are used for the work like that.

Bits of the drill Bits of the drill

The drill is used to make holes.

The bit of 3.2 mm is used for the screw hole of 3 mm.

Also the holes are made for attaching switches, terminals, lamps etc.

Therefore, the set of bits of some size is convenient.

As for the bits, metalworks is used.

The one of the photograph on the left, 13 bits are becoming a set.

Those are 1.5 mm, 2 mm, 2.5 mm, 3 mm, 3.2 mm, 3.5 mm, 4 mm, 4.5 mm, 4.8 mm, 5 mm, 5.5 mm, 6 mm and 6.5 mm.

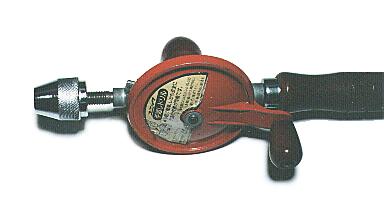

Handy drill Handy drill

Handy drill is convenient to make the hole by hand.

However, to make a hole in the iron board by this tool is terrible.

Electromotion drill Electromotion drill

This tool is convenient to make a lot of holes or to make holes to hard board like iron plate.

Reamers Reamers

This is a tool that enlarges the hole.

The drill is convenient to make a small holes. However, the bigger hole becomes needed to attach the switch, meter so on.

In the case, first, make a hole of 5 or 6 mm with the drill, after thst the hole can be expanded with reamer.

If the hole that expanded becomes near the needed size, it needs to check briskly.

When the hole is too big it is not attached the part well.

A big hole isn't built small.

Chassis punch ( Is this a Japanese English ? ) Chassis punch ( Is this a Japanese English ? )

The chassis punch is effective to the comparatively big hole. The chassis punch is effective to the comparatively big hole.

The chassis punch puts the board that wants to make the hole with the edge of male and female and attract both edges by using the bolt and make the hole.

Yet, the size of the edge is decided and only the hole of the size is opened.

The photograph is 5 steps of style things.

The upper side are the edge of a female, under side are the edge of a male and the hole can be opened to 16 mm, 18 mm, 20 mm, 25 mm, 30 mm.

Files Files

The files uses when the burr of the edge of the case is taken away. The files uses when the burr of the edge of the case is taken away.

Burr occurs to the part of the edge when a hole is made with the drill.

Burr of the drill in the case of, I turn and take the thicker drill a few times than the hole that opened it.

Also, I scrape it with a cutter knife, when there is not a thicker drill than the hole.

This method is easy.

Even with, files even something of it is useful.

Tap and the die Tap and the die

The tap is used when making the female screw. It is doing the form like the bit of the drill. It makes the screw with the side part of the blade. It makes a hole which is smaller a little than of the screw hole with the drill. In case of the screw hole of 3 mm, it makes an about 2.5-mm hole. The tap is used when making the female screw. It is doing the form like the bit of the drill. It makes the screw with the side part of the blade. It makes a hole which is smaller a little than of the screw hole with the drill. In case of the screw hole of 3 mm, it makes an about 2.5-mm hole.

The die is the one to make the male screw. It is it that is doing the circular form.

The tap and the die are used to have set in the handle of the exclusive use respectively.

The one of the photograph is the set of the tap and the die which the screw from 3 mm to 12 mm is composed of. |